Tim Reede Guitars Luthier Interview 1 Background

Tim Reede Guitars Luthier Interview 1 Background

Tim Reede Guitars Luthier – For those who don’t know you yet, can you tell us about your background? Did you go to Luthiers school? Did you follow a training with already established Luthiers? And, if you don’t mind my asking, what did you do before embarking on this adventure? Were you a musician before becoming a luthier? Or did you do anything else? And, by the way, do you still find time to play music with your work as a Luthier ?

I started as a craftsman about the same time I started playing guitar in 1982.

I was working in a machine shop using a metal lathe.

Later, I studied sound engineering in Ohio in 1986, then moved to Minneapolis and worked at a record store called the Electric Fetus.

In 1989 I started playing in a band. In 1994 I went to school for woodworking. I worked as a cabinetmaker for many years after that. It wasn’t till I got into playing acoustic guitar that I started thinking about building one.

I always played electric guitar before that.

There is a school in Minnesota that teaches guitar making, so in 2004 I quit my job and went back to school.

After that I went back to work at the cabinet shop and began building guitars in my spare time. I no longer build cabinets but I do work for the guitar school where I learned lutherie.

Between that and building guitars, I don’t have much time to play music regularly now.

Apart from creating custom instruments, we know that you do all types of repairs and maintenance on guitars and basses, can you also take care of other types of plucked and bowed stringed instruments?

After I left the cabinet shop, I was doing repair work as a subcontractor for a couple of instrument shops around town.

It was almost always acoustic and electric guitars and basses, occasionally a mandolin or a ukulele.

Tim Reede Guitars Luthier – Can you tell us about your current flagship models? Do you have a range that you do regularly? Do you also make unique custom models ? How did you proceed to create them ? What were your choices and your creation process? What kind of musicians do you cater to?

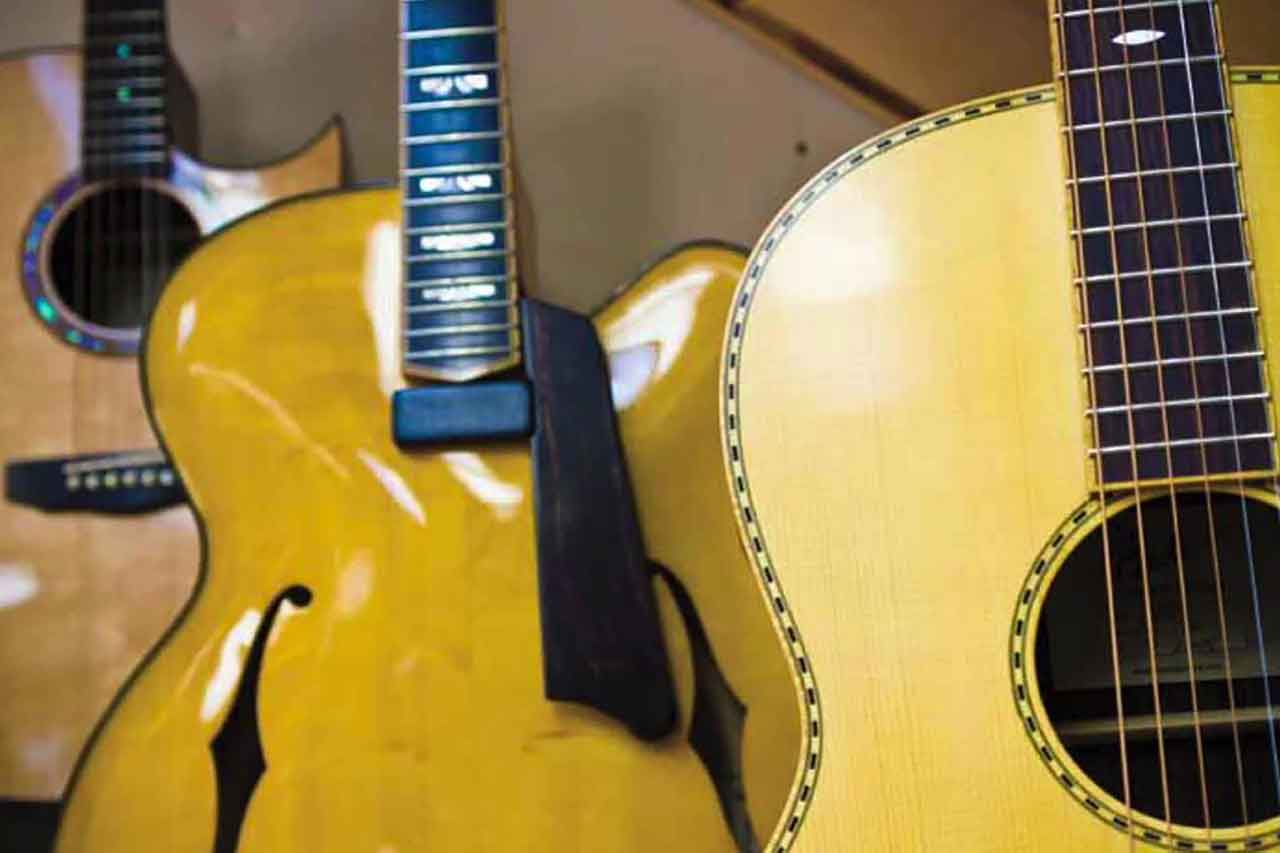

The Nomad and the Falcon are probably the most popular acoustic models that I make.

These are derived from classic historic designs, although I have made many modern design changes, and the materials that I use are often different too. I also have my own unique designs in the Librada and the Mercury.

The Librada is an acoustic/electric guitar that is very popular too.

It is built like an acoustic guitar, with an X brace and a spruce top. It has two pickup systems, electromagnet and piezo and two output jacks. So you can combine the pickups or you can process the signals separately. It is a versatile guitar with a small and comfortable body.

The Mercury is a chambered solid body electric guitar with a unique style of its own.

For my acoustic guitars, the body shapes are not customizable, except for adding a cutaway.

But all of my guitars are unique and most often the materials are chosen by the customer.

Sometimes they want an inlay designed specifically for them, or they may want a wider nut, arm bevels, side ports, different scale length, or a multi-scale fingerboard. On electric guitars, changing the shape is much easier, so if someone wants to change that, I can do that too.

To answer the last part of that question, most of my customers are finger-style acoustic players.

Some are professionals that are highly respected, others are couch players that just want a really nice instrument.

Computer has become everyone’s daily life, regardless of their profession. Do you use special computer tools in the field of Luthiers? Can you tell us about them?

I do use a computer design program for some things.

It is most helpful with custom electric guitars to draw the body shapes and bridge and pickup locations, but it comes in handy for rosette and inlay designs too. I also have a computer controlled router that I use for electric guitars, multi-scale fingerboards and a couple other things.

Tim Reede Guitars Luthier – Those who know you know that you are a great lover of beautiful woods, how do you help your customers to choose the woods of their future guitar in relation to the sound they have in mind? Can you easily find wood in your networks? If so, can you name some of your suppliers ?

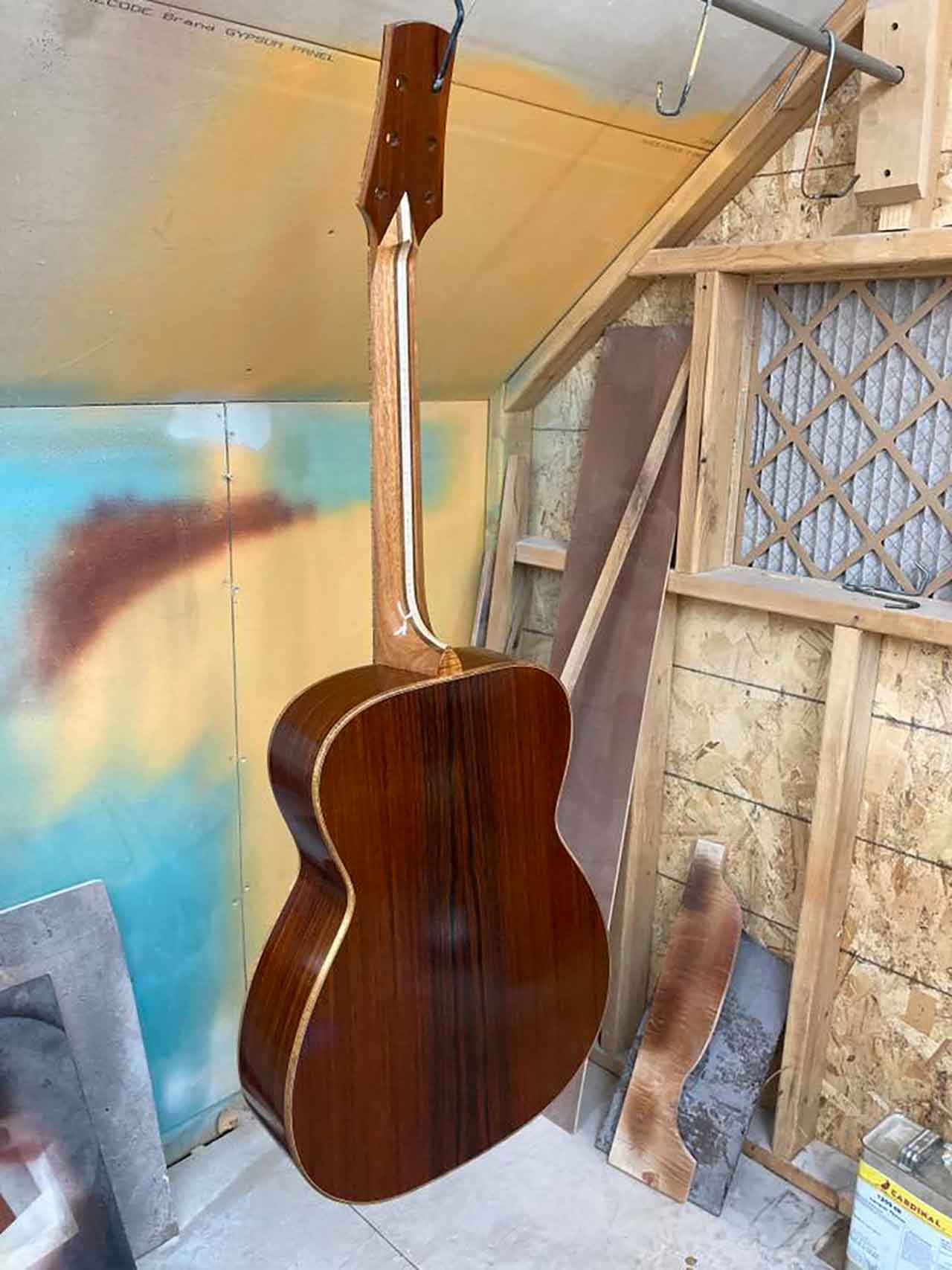

Wood choice is very important. Not just the species but also the way the wood is cut and dried.

So I am very picky about the wood that I use. For sound quality, it can often be a matter of personal preference but I can say that we consider the size of the acoustic body and how the guitar will be used. Will the player be playing solo or with a group? Do they use a pick? etc.

Some woods are bright sounding and can work well with a larger body where the instrument is naturally bass heavy. Solo players often want an instrument with a wide frequency range with a lot of sustain, while players in a group might be better served with an instrument that is more midrange focused to cut through the mix. Once we establish these parameters, it narrows it down, and then choices can be made based on other criteria, like cost or esthetics.

I don’t have much problem finding woods. Occasionally something will be hard to find.

I use Luthiers Mercantile International, Hibdon Hardwoods, Bow River Wood, RC Tonewoods, Notable Woods, Eurotonewood, Gilmer Wood and many more.

There is a huge selection of aftermarket parts. Do you work with regular suppliers or are you always on the lookout for new suppliers who can offer you something new? Do you have any examples to give us?

I can use any product upon request but I do have several suppliers that I use regularly.

Ameritage cases are very nice, K&K pickups are great, Gotoh tuning machines are very nice, Lollar pickups and Hipshot are quality products that I often use for electric guitars.

When you can’t find the parts you want at your aftermarket suppliers, do you ever create parts yourself or hire specialized craftsmen? Can you give us some examples?

If it is a wooden part or an inlay, I will make it myself, with a few exceptions.

Otherwise I do not dabble in making pickups or hardware.

I trust the professionals who have been doing that for years.

Tim Reede Guitars Luthier – How do you choose the pickups for your electric instruments according to the demands of your customers? Do you have any secrets or wiring habits? Have you ever had any very special requests, or requests that seemed strange to you from customers with special needs?

It really depends on the instrument.

For electric guitars I always prefer a hand wound electromagnet pickup. If a client wants something specific I can do whatever they want.

There have been a few unusual requests, but those are mainly about the design and not as much about electronics.

I guess that is why a customer would want a custom instrument made for them.

For example, I had one client that used a violin bow to play his electric guitar, so special accommodations were made for a tight fingerboard radius and they also wanted to play the strings between the bridge and the tailpiece so that was given more space.

I have also done lighted side dots using fiber optics so that was unusual too.

Tim Reede Guitars Luthier – Varnish… Nitrocellulo, P.U (polyurethane) or “pad” varnish? What are your choices and why?

I use nitrocellulose lacquer top coat for the repairability but I will use a UV cure sealer and clear grain filler.

This gives a flat and stable surface to lay the lacquer on top.

Tim Reede Guitars Luthier – How do you help your customers choose their electro-acoustic sensors?

I will recommend K&K piezo pickups and their internal microphones.

They have great bass response and the mic adds a sparkle and airiness to the top end. They have an external preamp that allows the player to blend the two sources.

I prefer the soundboard transducers like these over the under saddle type piezo.

Tim Reede Guitars Luthier – How do you help your clients choose the woods for the fingerboard of their instrument in relation to the sound they want to achieve? Can you tell us how this choice affects the other woods used in the construction of an instrument?

Fingerboards can affect the sound in small ways.

Rosewood adds a little sparkle. I like ebony too, but for other reasons.

It holds frets well, it looks great and it wears very little.

Tim Reede Guitars Luthier – Are you also interested in making amps and effects? And, if not, are you going to go in that direction like many other luthiers ? Or do you prefer to leave this part to others? (If you know the names of friends who are in this field, can you name some of them? 😉 )

I do not make amps or effects.

But I do know a few builders. Metz Amplification, Savage Audio, Casey Gooby makes nice amps and pedals, and Humphrey Amps makes beautiful acoustic guitar amps.

Tim Reede Guitars Luthier – Do you have any advice for future young luthiers? Can you give them advice on training courses? Do you know of any special schools?

I do recommend that aspiring luthiers go to school.

There are quite a few good ones out there. As I mentioned earlier I teach guitar repair and construction at the Minnesota State College Southeast in Red Wing Minnesota. Also the Galloup school of guitar building and repair, and Roberto Venn School of Lutherie are also highly regarded.

Tom Bills also does an online school called The Luthier’s EDGE.

Tim Reede Guitars Luthier – The profession of Luthier is a trade that requires a significant material investment to start its activity. What would you advise a young luthier to buy to start? The minimum required? And, the maximum to be in a comfortable working environment?

Clearly, building guitars requires much more investment than doing instrument repair work.

And there is more work out there for repair people. So I recommend that anyone that wants to get started begin there.

You will still need many specialty hand tools, but a small bench power sander, a router, a small bandsaw and a drill press is probably enough to start doing repairs,

then someone can grow from there.

You can contact Tim Reede through the contact form

on his personal page on Luthiers.com here:

https://luthiers.com/listing/tim-reede-guitars/

We also invite you to follow him on his various social networks:

- Facebook: https://www.facebook.com/Tim-Reede-Guitars-105242812850602

- Instagram: https://www.instagram.com/1timreede/

- Pinterest: https://www.pinterest.fr/reedeguitars/tim-reede-custom-guitars/

- Youtube: https://www.youtube.com/user/reedeguitars/videos

- Website: http://www.reedeguitars.com

https://youtu.be/Zeo3qmdDcxU

Tim Reede Guitars Luthier

In the coming weeks, as for others luthiers for plucked string instruments, luthiers for bowed string instruments, amps & effects makers, wood & supplies dealers, lutherie events, jobs, schools & teachers subscribers on our site, you will be able to follow our series of mini-interviews dedicated to the fascinating world of luthiers.

See you soon…

#luthiers

Subscribe to the newsletter!

Subscribe to our newsletter to follow all our news and those of our luthiers.

If you are passionate about the world of luthiers, join us!