Tasmanian Acoustic Tonewood Interview 4 Manufacturing process

Tasmanian Acoustic Tonewood Interview 4 Manufacturing process

For some of our Internet users who are not yet very familiar with the techniques related to your profession, can you explain us your complete manufacturing process. From the birth of a tree to the making of a set for an instrument?

There are many many life paths in which the material used to create a guitar has come from.

To answer this question, I will use Tasmanian Blackwood as an example.

After the tree has reached a mature age of approximately 60-80 years it is then either felled, starts to die or is forced over in a wild Tassie storm. We then search for these trees/logs assess their usability and cut it to lengths that are manageable for our mill and move it to the milling location.

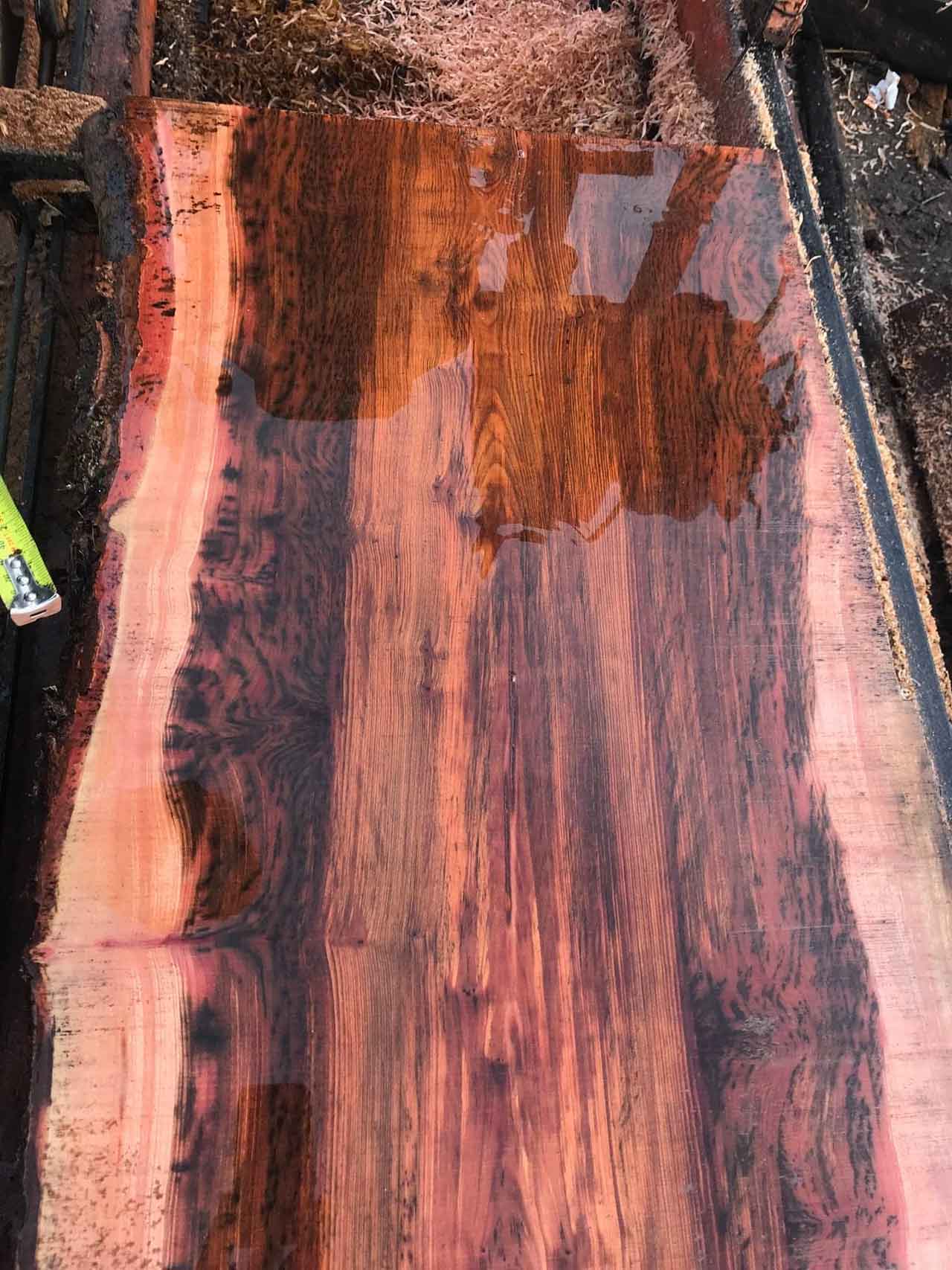

Each log is carefully inspected for quite some time (often too long) in order to achieve an understanding as to how it will be best processed into quarter sawn flitches/cants, the quartered pieces are then cut on a bandsaw mill.

Once sawn each piece is then inspected again and sometimes run over a table saw to remove any unnecessary live edges or defects.

After each flitch is trimmed and washed, we photograph, measure and document each piece so that we can track our stock well into the future.

This often happens when we are racking the timber which is a process of carefully laying each board very flat with a perpendicular racking stick across the board to allow air flow while it dries.

This is a very crucial and time consuming part to get perfect, if not racked correctly then timber movement in the way of twisting, cupping or cracking can destroy some beautiful timber.

After many moons go by and my drum kit has has had a good workout 😉 the timbers are all inspected moved and re-racked to counteract any amount of movement.

After this the timber may lay for five plus years resting, breathing and relaxing.

It is then woken up and re-sawn, heavily inspected, graded, and sat on a shelf to rest again.

This is when a small percentage of that tree may earn the title of Tonewood.

The reaming material is used for fine furniture or craft, zero waste.

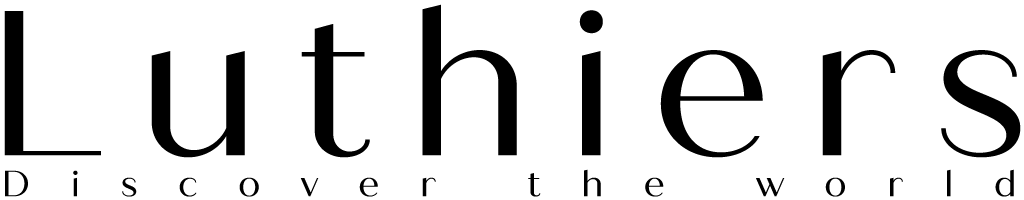

We then photograph each book matched set, measure, inspect again and list each individual set online for Luthiers to choose effortlessly!

The Luthier then creates the musical masterpiece for the world to see and hear for generations to come.

Tasmanian Acoustic Tonewood Interview 4 Manufacturing process :

Tasmanian Acoustic Tonewood are located in Tasmania (Australia), you can drop in by appointment or they can ship our products to you anywhere in the world!

Their goal is to supply Luthiers with premium quality Tonewoods for Acoustic Instruments all over the world.

With over two decades of experience in Tonewood milling, machining and drying, they are able to supply Luthiers with the very best Tonewood available.

Their standard of quality gives them confidence to offer a full money back guarantee upon delivery, taking any financial risk out of buying top quality Acoustic Tonewood online.

All of their Acoustic Guitar Tonewood kits are long-term air dried and ready to be crafted into your next masterpiece.

Tasmanian Acoustic Tonewood Interview 4 Manufacturing process : Luthiers Wood & Supplies dealers

You can find it on Luthiers at this address: https://luthiers.com/listing/tasmanian-acoustic-tonewood/

Some pictures of

Tasmanian Acoustic Tonewood

handpicked by our team

In the coming weeks, as for all the others luthiers for plucked string instruments, luthiers for bowed string instruments, amps & effects makers, wood & supplies dealers, lutherie events, jobs, schools & teachers registered on our website, you will be able to follow our series of mini-interviews dedicated to the fascinating universe of luthiers.

See you soon…

#luthiers

Subscribe to the newsletter!

Subscribe to our newsletter to follow all our news and those of our luthiers.

If you are passionate about the world of luthiers, join us!