Luthier Quentin De Leeuw Guitars Interview 1 Background

Luthier Quentin De Leeuw Guitars Interview 1 Background

Vous pouvez également découvrir cette interview en français https://luthiers.com/de-leeuw-guitars-luthier-interview-1-background/

Luthier Quentin De Leeuw – For those who don’t know you yet, can you tell us about your background ? Did you go to a luthier school ? Did you follow a training with already established luthiers ? And, if it’s not indiscreet, what did you do before starting this adventure? Were you a musician before becoming a luthier ? Or were you doing something else ? And, by the way, do you still find time to play music with your work as a luthier?

As for my training, well, I don’t have any diploma in luthier. On the other hand, I was trained a lot in the art trades around the wood, in the high school of the art trades of Saint Quentin.

When I graduated from high school, I was a guitarist, and luthier was the way I wanted to go.

So I went on to complete a CAP (cabinetmaking, marquetry, sculpture), as well as a brevet des métiers d’art in cabinetmaking.

The goal was to acquire all the necessary skills to master the subject.

During these 5 years of training, I was able to do internships with Frédéric Beaudoin, guitar luthier in Bailleul-sur-Thérain.

I also started to build my first electric guitars, and towards the end of the course, at 21, I set up my own workshop (“L’accord du bois”, which became “De leeuw Guitars“).

With the lutherie, there is inevitably a little less time to practice the instrument, but I manage to keep the pleasure of playing.

I play in a band. Making music in a band is also something exciting, the studio, the stage…

It is very inspiring as a luthier to understand some of the issues related to these moments and to be able to bring interesting solutions to them.

Can you tell us about your flagship models of the moment? Do you have a range that you do regularly ? Do you also make unique custom models ? How did you proceed to make them ? What were your choices and your creation process ? What kind of musicians are they for ?

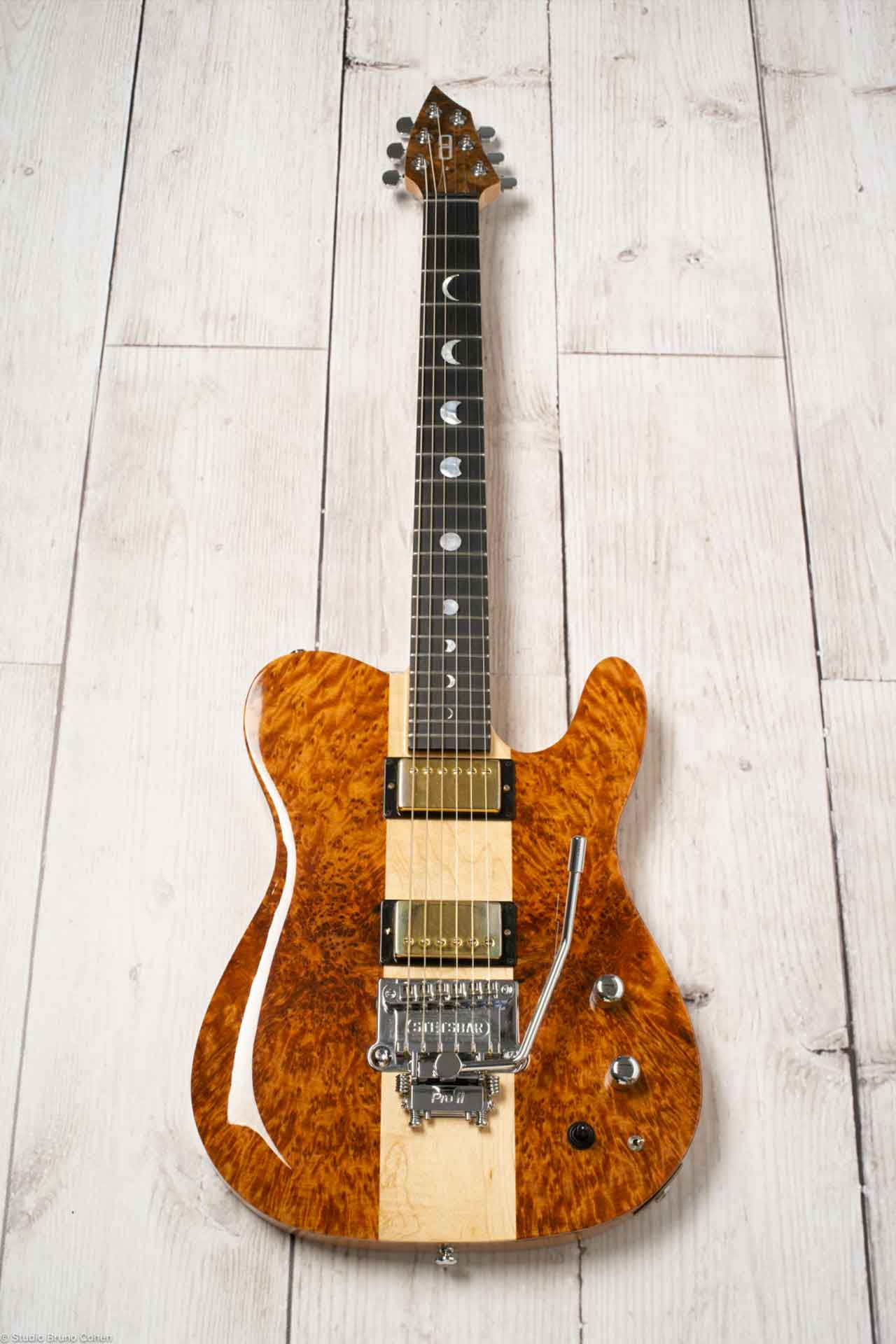

The model that is really our shape and our “signature” is the “MS” model which exists in 6 and 7 strings.

We produce them all year long in different wood assemblies, and therefore with different looks.

We are currently producing the “MS” model in 2 limited series of 6 pieces each. 6 pieces only because we only found a limited quantity of wood to produce these models exactly as we designed them (you can find them on our website in the “Limited series” section: https://deleeuw-guitars.fr/series-limitees/).

Of course, we produce 100% custom guitars every year, and each one is unique.

In the workshop, we spend a lot of time looking for woods and assemblies that will allow us to offer truly different guitars. We always have in mind a search for excellence in the forms as well as in the techniques of implementation. We are proud to say that each guitar is handcrafted with the greatest care, and that every detail is thought out for the pleasure and comfort of its future owner.

In fact, and being attentive to musicians, we can design a jazz guitar as well as an extreme metal guitar.

We are therefore ready to work with all exigent musicians 🙂

Luthier Quentin De Leeuw – Computers have become a part of everyone’s daily life, no matter what profession you practice. Do you use particular tools in the field of lutherie. Can you tell us about them ?

No, we are currently adept at “handmade”.

The workshop will inevitably evolve one day and we will make our tools evolve, but it will be done in the respect of the know-how and the quality that we claim.

Those who know you know that you are a big fan of beautiful woods, how do you help your customers to choose the woods of their future guitar according to the sound they have in mind ? Are you able to find wood easily in your network ? If so, can you name some of your suppliers ?

Indeed, the beautiful wood species will always be put forward at the workshop.

This is linked to my professional career (I obtained all the diplomas from the school of arts and crafts in Saint-Quentin).

By dint of researching and experimenting with different blends of different species, we are necessarily able to respond to specific requests.

Guitar and bass players often come with sound references in mind and we have to find them the right woods. We also have to take into account the whole sound chain that goes with it, including the pickups. A good pickup must sublimate the wood species as well as the quality of the lutherie.

This is what makes our job so magical and exciting. Overall we always find beautiful pieces to design and produce our guitars.

We work with Kauffer and Maréchaux, but there are many others. 😉

Luthier Quentin De Leeuw – There is a huge choice of aftermarket parts. Do you work with regular suppliers or are you always on the lookout for new suppliers who can offer you something new? Do you have any examples to give us?

We try to work with few suppliers, in order to know the qualities of the different parts.

As a “maker of exceptional instruments” we must choose parts that meet our standards of excellence.

Knowing our suppliers well means being able to have a privileged dialogue with them. It is from this permanent exchange that the evolutions of certain parts of fittings are born or that we obtain really unique pickups for our customers.

For example, we work with few pickup manufacturers, but we know that with them, the customer will get exactly what he is looking for. At the moment we are working closely with a pickup manufacturer to bring out a new pickup that is not in their catalog.

And, of course, we have to be aware of all the new developments in order to always be able to offer the best on our instruments.

Luthier Quentin De Leeuw – When you can’t find the parts you want from your aftermarket suppliers, do you sometimes create parts yourself or use specialized craftsmen? Can you give us some examples?

The only parts we have to make are the nuts and sometimes the bridges.

But in general, we find everything we need from our suppliers.

They manage to answer all our requests… Even the most outlandish 🙂

How do you choose the pickups for your electric instruments according to the requests you get from your customers? Do you have any secrets or habits in terms of wiring? Have you ever had very particular requests, or requests that seemed strange to you from certain clients who had particular needs?

The choice of the pickups is made in knowledge of the wood species in order to restore the best of the instrument.

As with everything else, it’s all about the dialogue. Is the customer looking for versatility? An ultra typical sound? Everything is possible.

Moreover, we work with craftsmen who, like us, have a love for work well done and make pickups by hand, with love and within extremely short deadlines.

Making a lot of 100% custom guitars, we are able to respond to all requests, even the most exotic.

In terms of instruments, nothing is strange since it meets a demand that is often well thought out by the musician.

We have already mounted Seymour Duncan P-rails with a Piezo in the bridge, and all with a push/pull system allowing to do without the “triple shot” connectors of the brand. In total, 24 possible positions + the mix with the Piezo.

For our own instruments or limited series, we are quite classical on the wiring, which does not exclude trying more personal things in the future.

Luthier Quentin De Leeuw – Varnish… Nitrocellulo, P.U (polyurethane) or French polish ? What are your choices and why?

We favour two techniques, even if we can answer all requests.

We like the natural look of oiled wood, it allows the wood to breathe and age “naturally”. This is what we mainly offer on our instruments.

When we do varnish, we mainly choose polyurethane varnish, because it has a better resistance and avoids the “plastic” aspect that sometimes happens on unpainted guitars.

The wood is thus magnified.

Luthier Quentin De Leeuw – How do you help your customers to choose their electro-acoustic sensors?

The choice of electro-acoustic sensors is often dictated by the instrument itself.

It depends if it’s for a “creation” or for an upgrade on an existing guitar.

How do you help your customers to choose the fingerboard wood for their instrument in relation to the sound they want to obtain? Can you tell us about the impact of this choice in relation to the other woods used in the construction of an instrument?

The choice of the fingerboard is linked to a logic of association with the other woods making up the instrument.

Once the necessary density is determined, the question of aesthetic choice arises.

We can for example, find very black ebony or other very figured, while remaining in a high density. Obviously, sometimes we will choose a wood more or less “oily / rich”.

All this plays effectively on the final sound as well as the precision of the note.

Luthier Quentin De Leeuw – Are you also interested in building amps and effects? And, if not, are you going to go in this direction like many other luthiers? Or do you prefer to leave this part to others? (If you know names of friends who are in this field, can you name some? 😉 )

We know plenty of people who do this very well.

We know them and recommend them to our customers. It is not the order of the day to become an electronics / acoustics specialist.

This is another job…

🙂

Do you have any advice to give to future young luthiers? Can you give them advice on training? Do you know of any specialized schools?

Passion… And a lot of work.

There are schools, some of which are abroad.

It is important not to forget that the “cabinet making” type of studies give knowledge in terms of woodworking, which is very useful.

And of course, to know if you want to make electric guitars or acoustic guitars, because those are different techniques.

Luthier Quentin De Leeuw – The luthier’s job requires an important material investment to start his activity. What would you advise a young luthier to buy to start ? The minimum required ? And, the maximum to be in a comfort of work ?

You can start with very few materials.

A saw and chisels are part of the basic elements. Of course, a good drill and a good ripper are always a plus.

In any case, a good working space must be prepared. It is necessary to be able to install correctly and to leave the elements “under pressure” during the gluing time.

Think minimum safety equipment! It is very important!

The projections of wood or products are quickly arrived… And attention to the fingers 🙂

After that, there is no limit in terms of equipment. The trick is to find what is best suited to your working methods.

Luthier Quentin De Leeuw Guitars Interview 1 Background

You can contact Quentin De Leeuw, founder of De Leeuw Guitars (DLG) through the contact form on his personal page of Luthiers.com here : https://luthiers.com/listing/de-leeuw-guitars/

We also invite you to follow him on his various social networks:

- Facebook : https://www.facebook.com/DeLeeuwGuitars

- Pinterest : https://www.pinterest.fr/Deleeuwguitars/_created/

- Instagram : https://www.instagram.com/deleeuwguitars/

- Youtube : https://www.youtube.com/channel/UCbl6ajJslx797c4OtU9JieA

Quentin De Leeuw, fondateur de De Leeuw Guitars (DLG)

At the origin of De Leeuw guitars, there is the Accord Du Bois. A lutherie workshop located in Compiègne in the Oise region.

Today, the workshop offers you all its productions under the same name: De Leeuw Guitars.

Everything happens in the workshop in Compiègne. Any instrument bearing the initials De Leeuw Guitars is made there. No digital machines, here, everything is made by hand, according to the rules of art.

In order to offer you original instruments, ergonomic and sticking point by point to your musical wishes, I put at your disposal all my luthier knowledge.

Passionate for many years about music, instruments and the whole universe they represent, I have been looking for techniques and theory to design my instruments in the best way.

This has led me to work with wood in a general sense, marquetry, sculpture, but also by practicing my instrument assiduously, especially in groups and on stage.

The result of all this, the possibility of understanding your request at best at the time of the design of your instrument, to propose you the best solution for guitars and basses without concessions.

Quentin De Leeuw.

History

A brief history of De Leeuw Guitars :

- 2013-2018: studies of wood and guitar techniques (cap cabinetmaker, marker, sculptor, BMA cabinetmaker).

- 2015 : First guitar with the “De Leeuw Guitars” logo

- 2016 : Creation of l’Accord Du Bois, a lutherie workshop, in the former buildings of Pontpoint, first production of guitars.

- 2018 : Expansion of the company, installation in the buildings of Compiègne

- 2020 : Officialization of the brand DLG (De Leeuw Guitars)

Discover videos of the creations

De Leeuw Guitars

In the coming weeks, as for others luthiers for plucked string instruments, luthiers for bowed string instruments, amps & effects makers, wood & supplies dealers, lutherie events, jobs, schools & teachers subscribers on our site, you will be able to follow our series of mini-interviews dedicated to the fascinating world of luthiers.

See you soon…

#luthiers

Subscribe to the newsletter!

Subscribe to our newsletter to follow all our news and those of our luthiers.

If you are passionate about the world of luthiers, join us!