Ute Zahn Luthier Interview 1 Background Violin maker

Ute Zahn Luthier Interview 1 Background

Ute Zahn Luthier – For those who don’t know you yet, can you tell us about your background? Did you go to Luthiers school? Did you follow a training with already established Luthiers? And, if you don’t mind my asking, what did you do before embarking on this adventure? Were you a musician before becoming a luthier? Or did you do anything else? And, by the way, do you still find time to play music with your work as a Luthier ?

I moved to England from Germany, where I grew up, to train at the Newark School of Violin Making a year after graduating from high school.

I had spent the intervening year doing some volunteer work, which I was (and am) passionate about.

I had started playing the cello at the age of ten, but didn’t think I had the temperament to be a performer. I wasn’t much of a “people person”!

Thirty-some years later, I still feel like I am a luthier-in-training.

I still play the cello and have learned to enjoy performing.

Apart from creating custom instruments, we know that you do all types of repairs and maintenance on bowed strings instruments, can you also take care of other types of plucked stringed instruments?

When I lived in Hong Kong, I worked on several ancient qins (a form of traditional Chinese zither).

On the whole, I feel that intricate instrument work is best left to the experts, and I feel most comfortable working on violin-family instruments.

Ute Zahn Luthier – Can you tell us about your current flagship models? Do you have a range that you do regularly? Do you also make unique custom models ? How did you proceed to create them ? What were your choices and your creation process? What kind of musicians do you cater to?

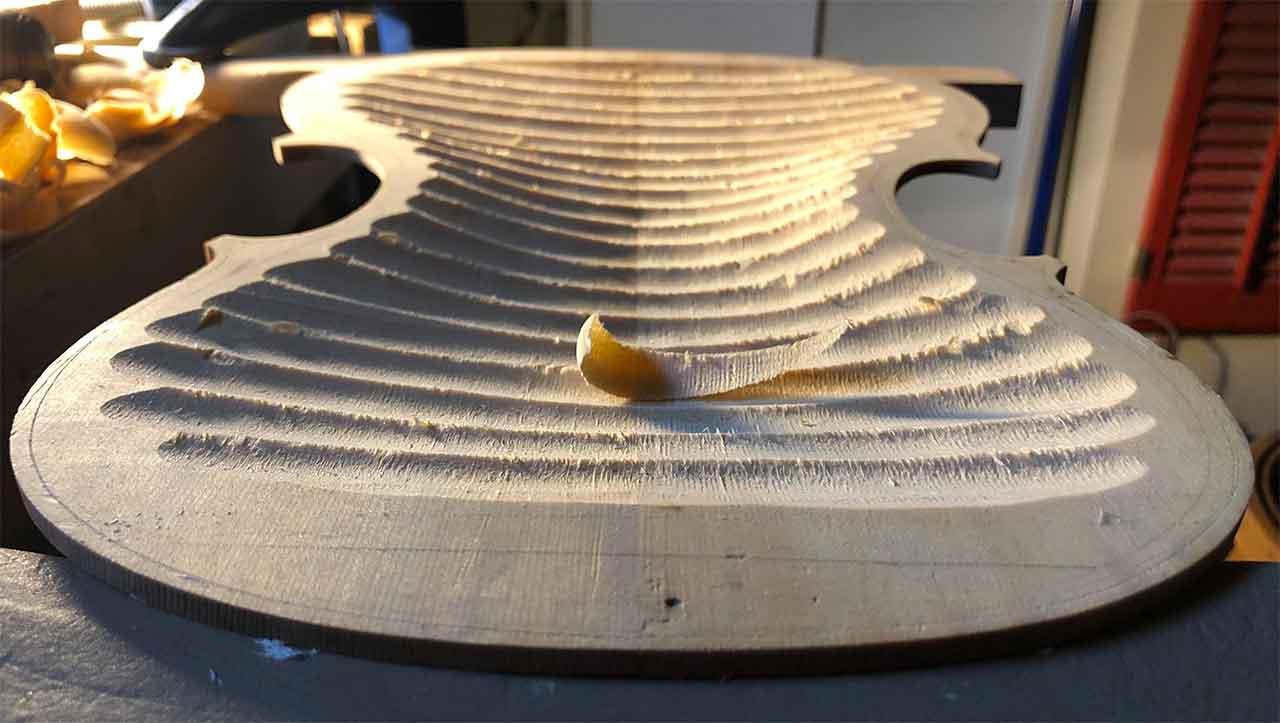

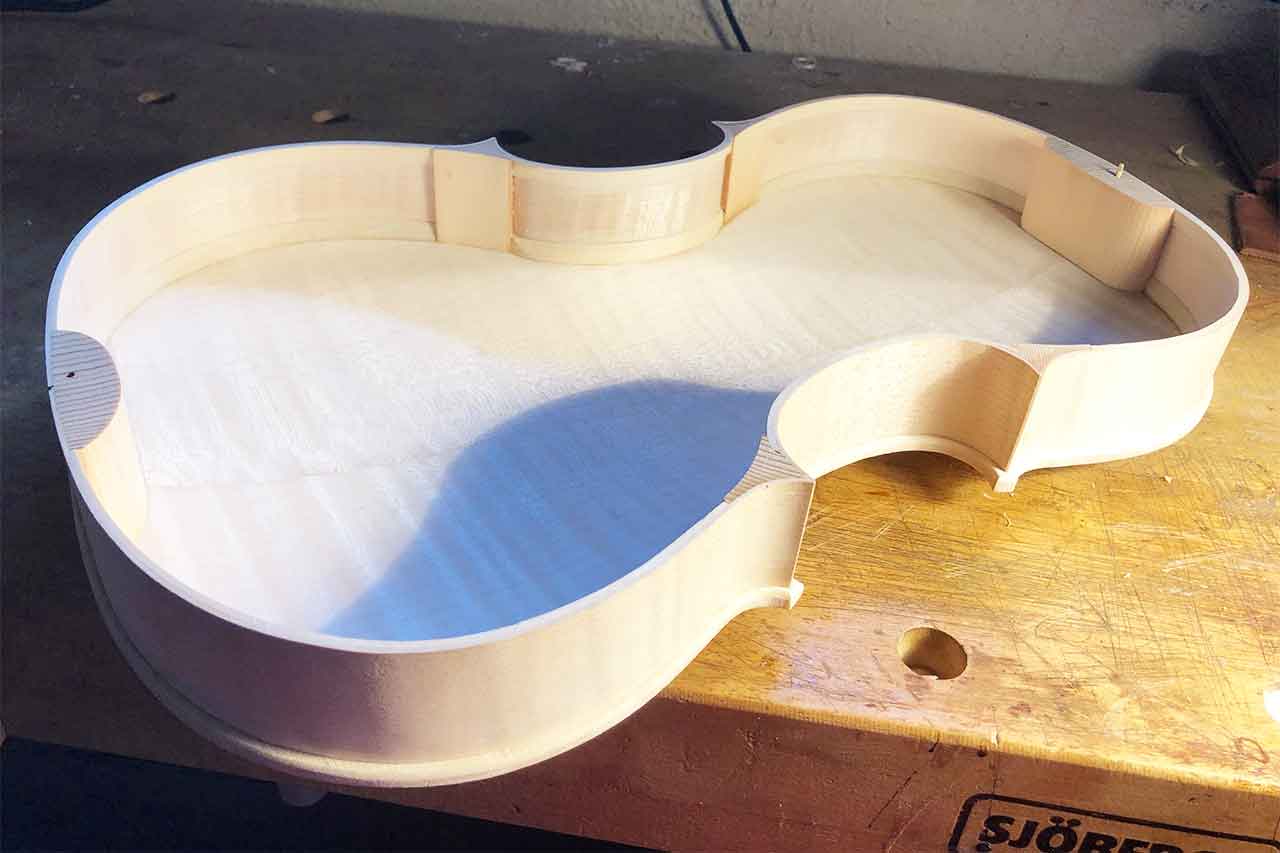

I have a few models I come back to regularly — but I do not make exact copies.

Rather, I prefer to use an existing model as a starting point and adapt it to my taste, and to what I think is going to create the sound I am after.

This sometimes means changing the shape of the arching, or the plate thicknesses; or adjusting the size and layout of the soundholes.

I have made unique models on occasion.

It has been interesting experimenting with my own outlines and finding out all the things I didn’t consider in doing so! I am open to working with customers to arrive at a model which suits them.

My clients are a mix of professional and amateur players, most of them classical musicians.

Computer has become everyone’s daily life, regardless of their profession. Do you use special computer tools in the field of Luthiers? Can you tell us about them?

Computers might be useful, but they aren’t my favourite tool!

I have used computer drawing tools, but prefer to use a compass and ruler.

I have also used software to create thickness maps of the instruments I make, and I use recording software to measure plate frequencies. But as far as really making computers work for me, I feel I am a little behind the curve.

The most use I get out of computers is probably in the area of marketing — having a presence on social media and designing things like brochures etc.

Ute Zahn Luthier – Those who know you know that you are a great lover of beautiful woods, how do you help your customers to choose the woods of their future instruments in relation to the sound they have in mind? Can you easily find wood in your networks? If so, can you name some of your suppliers ?

Stragely, most musicians I know are not really focused on the choice of wood for their instrument.

They tend to trust me to make a good choice for them.

My wood buying is a little haphazard. Whenever I go to the VSA conventions, I pick up a few pieces — from Bachmann, Pahler, Old World Tonewoods. I have bought some tonewood from Tom Core, and occasionally order wood online from Tonewoods SK.

Some pieces come my way “accidentally” when colleagues are looking to offload extra wood, or someone passes away.

Ute Zahn Luthier – There is a huge selection of aftermarket parts. Do you work with regular suppliers or are you always on the lookout for new suppliers who can offer you something new? Do you have any examples to give us?

It is always interesting to try out new fittings, but mostly I tend to go with tried and trusted suppliers.

When you can’t find the parts you want at your aftermarket suppliers, do you ever create parts yourself or hire specialized craftsmen? Can you give us some examples?

I try to plan ahead so I do not end up in this position!

However, before Covid I was looking to have a local craftswoman make some parts for me … but with the pandemic, I set that plan aside for now as my economic future is a bit uncertain.

Ute Zahn Luthier – How do you choose the pickups for your electric instruments according to the demands of your customers? Do you have any secrets or wiring habits? Have you ever had any very special requests, or requests that seemed strange to you from customers with special needs?

My experience with electric instruments is limited to one electric violin I made, years ago.

If I were to embark on it again, I would definitely have to do my research!

Ute Zahn Luthier – Varnish… Nitrocellulo, P.U (polyurethane) or “pad” varnish or others? What are your choices and why?

I cook my own varnish from very traditional materials — rosin, linseed oil and turpentine.

I enjoy it and I feel it gives me the results I am looking for, and the flexibility to change as required.

Ute Zahn Luthier – How do you help your clients choose the woods for the fingerboard of their instrument in relation to the sound they want to achieve? Can you tell us how this choice affects the other woods used in the construction of an instrument?

This is honestly a question which has never come up.

I would say the only advice I would give to customers is to choose the provenance of all of their fittings wisely, and only buy tropical hardwoods from sustainable sources.

Ute Zahn Luthier – Do you have any advice for future young luthiers? Can you give them advice on training courses? Do you know of any special schools?

If you are thinking about becoming a luthier, you have to really love making instruments, and you have to be prepared to be in it for the long haul.

Most people do not achieve success, or even a sustainable income level, overnight.

There are a number of reputable schools to choose from, depending on where in the world you are, or want to be.

I was very happy with the training I got in Newark and would still recommend the school to any aspiring luthier.

But at best, the schools will only give a good grounding; what makes lutherie so interesting is that there is always more to be learned.

There are also excellent courses for established luthiers such as the Violin and Bow Makers’ workshops in Oberlin and similar classe in West Dean, UK,

which provide a wonderful forum for keeping the enthusiasm alive and meeting new friends from all over the world.

Ute Zahn Luthier – The profession of Luthier is a trade that requires a significant material investment to start its activity. What would you advise a young luthier to buy to start? The minimum required? And, the maximum to be in a comfortable working environment?

There is no maximum!

I would advise to buy all the cutting tools first — knives, planes, chisels, gouges; and to not be cheap or stingy.

These tools will be your friends for a lifetime.

I personally have no machines other than a grinding wheel (which has lasted me 25 years or so, to date) and a drill press. My studio is quite small, so it would be hard to fit in anything else!

When I move to a larger space, I plan to get a good band saw.

I prefer to do all the other work by hand; because that’s why I went into violin making in the first place!

You can contact Ute Zahn through the contact form

on his personal page on Luthiers.com here:

https://luthiers.com/listing/ute-zahn-violin-maker/

We also invite you to follow him on his various social networks:

- Facebook: https://www.facebook.com/profile.php?id=100012549976975

- Instagram: https://www.instagram.com/ute.zahn/

- Website: http://www.utezahnviolinmaker.com

Discover Ute Zhan in her latest video

Class for the Curious Musician

A Night with a Violin Maker, Ute Zahn

Accomplished violin maker, Ute Zahn, shares the steps to violin making,

along with insights into it’s history and traditions.

Ute Zahn Luthier

In the coming weeks, as for others luthiers for plucked string instruments, luthiers for bowed string instruments, amps & effects makers, wood & supplies dealers, lutherie events, jobs, schools & teachers subscribers on our site, you will be able to follow our series of mini-interviews dedicated to the fascinating world of luthiers.

See you soon…

#luthiers

Subscribe to the newsletter!

Subscribe to our newsletter to follow all our news and those of our luthiers.

If you are passionate about the world of luthiers, join us!