Thomas Ochs Luthier Interview 1 Background

Thomas Ochs Luthier Interview 1 Background

Thomas Ochs Luthier – For those who don’t know you yet, can you tell us about your background? Did you go to Luthiers school? Did you follow a training with already established Luthiers? And, if you don’t mind my asking, what did you do before embarking on this adventure? Were you a musician before becoming a luthier? Or did you do anything else? And, by the way, do you still find time to play music with your work as a Luthier?

When I realized, that I want to build guitars, I already was enrolled at the university and studied biology and physics.

But I decided to do an internship at Hanika Gitarrenbau in my semester vacations and fell in love with the craft of guitar making. So I gave up my studies and started an apprenticeship at Hanika in 1996.

In Germany we have a dual system of vocational training in all crafts professions.

You work in a company and get your training there, but you also go to specialized schools to get theoretical instructions.

After my apprenticeship I worked for Hanika another year and went to Mexiko to meet Boaz Elkayam.

There I experienced what lutherie can be apart from producing lots of guitars.

With this in mind I applied for the studies of Musical Instrument Technology, a 4 year course in a beautiful Art Nouveau villa in Markneukirchen, Germany (http://www.studia-instrumentorum.de/merz.htm).

The goal of this study is to acquire the theoretical and practical knowledge and ability to enable the student to design and construct high-quality, artistically shaped musical instruments.

These 4 years really helped me to focus on the theoretical framework and the sound aspect of the craft. Apart from studying innovative concepts like the Kasha system or lattice bracing, I had the chance to study quite a few historical instruments in detail.

So I could develop my own genuine guitar models from various influences.

The funny thing about my career as a luthier is that when I started back in 1996 I wanted to do the apprenticeship at the classical guitar company Hanika and then start to build electric guitars in my own workshop as I played electric guitar myself.

But looking back it seems that I am stuck to building mainly classical guitars, even though I built many electrics the past years.

I am very happy, that I still can play some music with my band GLOOMFIRE.

We worship the almighty riff and play some heavy downtuned rock.

But listen yourself: www.bit.ly/gloomfire_spotify

Apart from creating custom instruments, we know that you do all types of repairs and maintenance on guitars and basses, can you also take care of other types of plucked and bowed stringed instruments?

The truth is, that I try to minimize the time I have to spend on repair jobs, as my focus lies on building new instruments.

I did a lot of repairs, while studying and when I started my own business back in 2004.

This helped me to get a good reputation and to get to know the guitar players in my area and beyond. But with more and more orders for new instruments, I want to focus my energy on building my own instruments.

And there is another important aspect, I want to mention:

In my experience, you need some kind of specialisation to become really good at what you do.

I know that I can solve most guitar related problems – electrics and acoustics already open a broad field here with many challenging tasks. But apart from guitars, I am not an expert at all and have only basic knowledge of other instruments.

However there are luthiers who specialize in and are experienced and skilled experts for these other instruments. For example in Germany violin maker is an independent profession, and I think it would be presumptuous to think my violin repair skills are as good as those of a trained violin maker.

Consequently I always sent costumers with bowed stringed instruments to a violin maker.

Thomas Ochs Luthier – Can you tell us about your current flagship models? Do you have a range that you do regularly? Do you also make unique custom models ? How did you proceed to create them ? What were your choices and your creation process? What kind of musicians do you cater to?

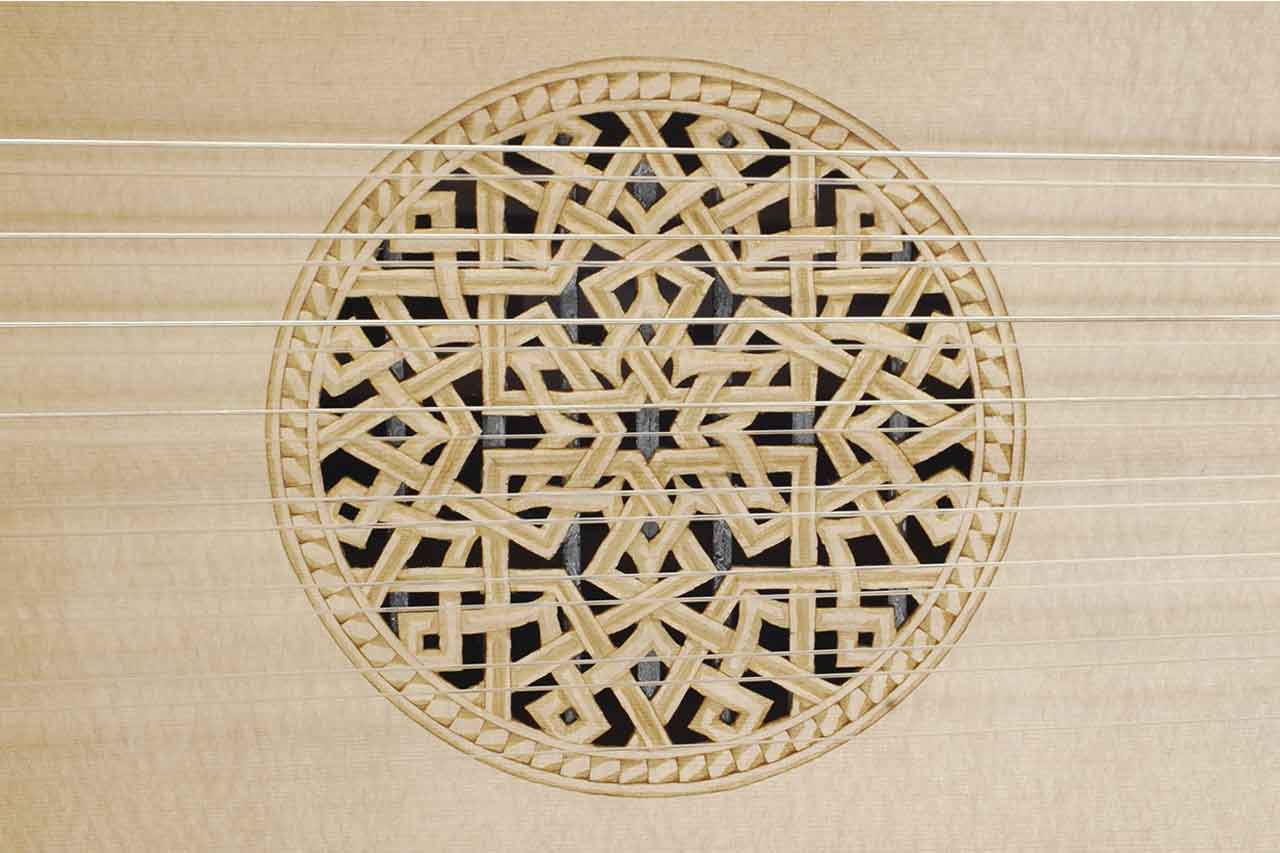

My approach to building guitars is to constantly reflect, improve and refine what I am doing.

So every new instrument demands my full attention and concentration.

I am very happy that I get orders for various types of guitars and that my portfolio includes classical, acoustic and electric guitars and even bass guitars.

But there are projects, which are outstanding, thrilling and challenging and therefore are the spice of the guitarmakers life.

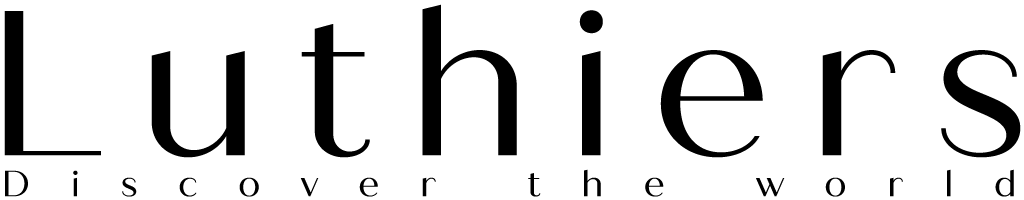

The past few years I created a classical guitar model, which combines the so called “Kasha theories” with the popular double top construction, invented by Matthias Dammann and Gernot Wagner.

Michael Kasha was an american physicist, who started to postulate quite controversal hypotheses about the construction of guitars in the late 1960s.

Together with Richard Schneider and others he developed a guitar design concept, based on acoustical considerations, which was radically different to traditional guitars.

This approach was very inspiring for me and I decided to dig deeper and do some research on this topic as my diploma thesis at the end of my studies in Markneukirchen (Read it here in German: https://www.ochs-gitarrenbau.de/media/diplomarbeit_www.pdf).

It was obvious that I also had to try the concept in real instruments, so I developed my own Kasha classical guitar model.

I found out, that the Kasha design principles and a lightweight guitar top, resulting from a sandwich construction, complement each other excellently.

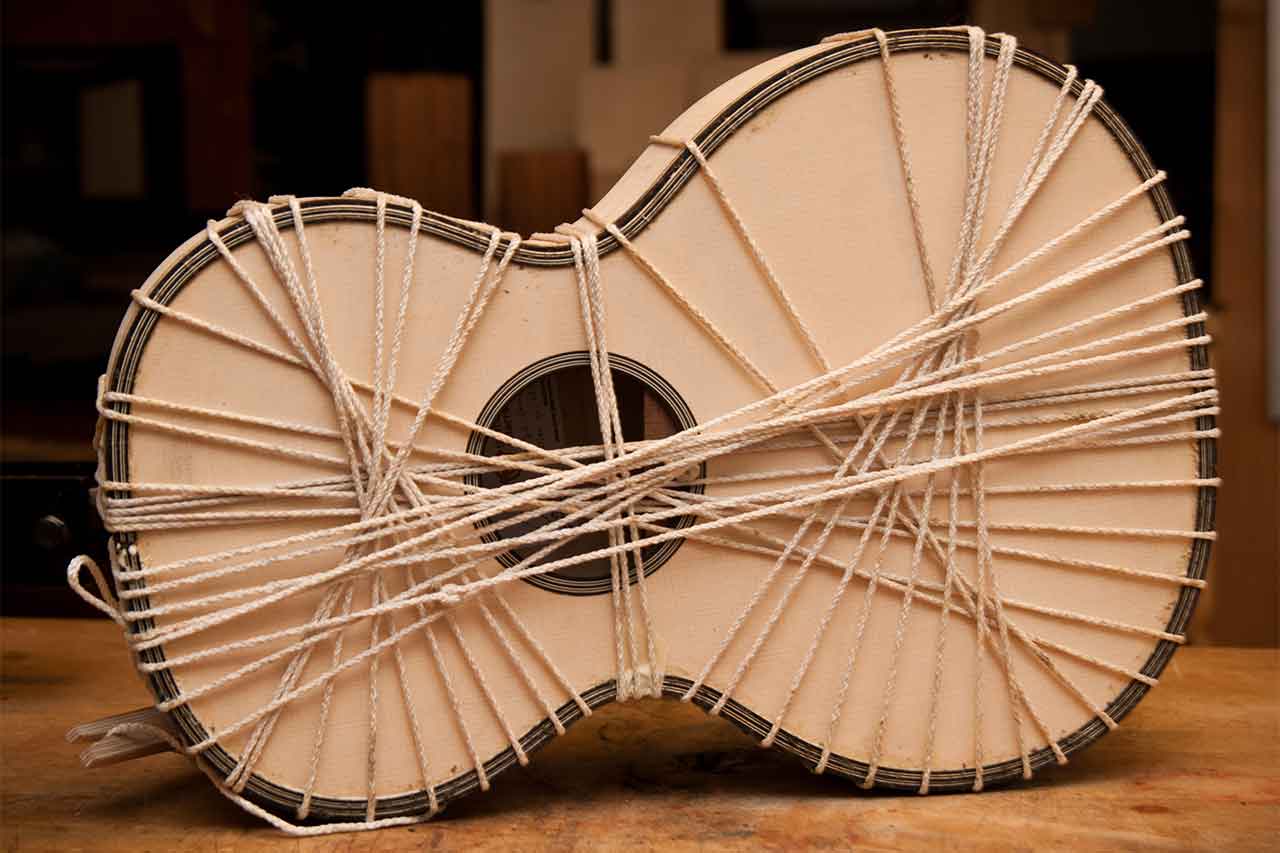

Therefore, to answer your question, my flagship model would be my classical guitar model “Kasha DoubleTop Multiscale”

On the other handside I also love my electrical guitar model “Model One“.

After playing a Gibson Les Paul for almost 20 years, I started designing an electric guitar some years ago.

But with the approach of a of a luthier having repaired hundreds of guitars and having seen the flaws of traditional electric guitar design.

My Les Paul was a heavyweight monster and to tell the truth, it sounded muddy when played with high gain distortion.

So after each band rehearsel, my back and ears where aching.

My Model One is a single cut guitar and of course in the tradition of a Les Paul or Paul Reed Smith. But with this model, I can realize a high end boutique guitar without any tropical woods and with so many nice features, that it is truly a luthier´s instrument.

It is lightweight, ergonomic and astonishes with her enchanting voice.

Every instrument I make is discussed in detail with the player.

Even with dealers, I try to figure out, what special features will help them to have a unique instrument in their product portfolio.

There are basic models, like my just mentioned electric “Model One” or the traditional classical guitar “Modell Konzert”, but these are only guidelines or examples.

Everything can be costumized, to fit the needs of the player.

Computer has become everyone’s daily life, regardless of their profession. Do you use special computer tools in the field of Luthiers? Can you tell us about them?

I would love to use more computer aid, as modern CAD/CAM can help to produce super accurate results.

But I am not well trained in this field and do not have the machines. But I use Adobe Illustrator for designing instruments and I use social media to stay in contact with people and for PR.

But who knows, I definitly would like to use the advantages of a CNC routing machine or a laser cutter.

Thomas Ochs Luthier – Those who know you know that you are a great lover of beautiful woods, how do you help your customers to choose the woods of their future guitar in relation to the sound they have in mind? Can you easily find wood in your networks? If so, can you name some of your suppliers?

I think the wood selection for an instrument is a very important part of the communication between the luthier and the player.

There are two very important aspects when we are talking about tonewood.

At first the term “tonewood” already states that it has an impact on the sound of the instrument.

But the choice of wood also defines the aesthetics of the instrument.

Let me give you an example: We know, that we can build a powerful, high end classical guitar, when using a spruce top in combination with back and sides made from eastindian rosewood.

But already the wood choice for the bindings affects our perception of the appearence of the instrument.

Ebony bindings give an elegant, sophisticated and somewhat posh appeal, while maple makes the instrument look more fresh, lively and smart casual.

So the way to a custom instrument is paved with decisions and the team player-guitarmaker has to find a good balance between the sound requirements and the desired aesthetics of the instruments.

Over the years I have bought wood from many sources.

There are many very good dealers specialising in tonewoods around the world and I would surely forget someone, when I try to name the ones I like.

There is a huge selection of aftermarket parts. Do you work with regular suppliers or are you always on the lookout for new suppliers who can offer you something new? Do you have any examples to give us?

With parts it is basically the same as with wood dealers.

There are many excellent suppliers of pickups, hardware, tuning machines, etc.

Some of them I know, with some I have worked know for many years, but I think it would be unfair to name just a few, because I know there are many out there I don not know they exist.

But I am constantly looking for new contacts and especially innovative solutions.

If you know, that there is something great out there, please let me know!

When you can‘t find the parts you want at your aftermarket suppliers, do you ever create parts yourself or hire specialized craftsmen? Can you give us some examples?

I try to do as much work as possible on my instruments by myself.

On classical and acoustic guitars, the only premade parts I need to buy are tuning machines, fretwire and the strings, I am a woodworker and I know, that I am not capable of producing tuning machines or fretwire.

Here again, I believe in specialisation and focus on what you really can do on expert level.

Electric guitars need more premade parts and luckily until now, I could get, what I needed to build my instruments.

But I would not hesitate to order custom parts for special projects from specialised craftsmen.

Thomas Ochs Luthier – How do you choose the pickups for your electric instruments according ot he demands of your customers? Do you have any secrets or wiring habits? Have you ever had any very special requests, or requests that seemed strange to you from customers with special needs?

Concerning pickups I am choosing from the wide range of products currently available.

After discussing the desired sound characteristics with the costumer I look which model and which supplier fits best.

I do not wire myself and there are no secrets. And I also know which supplier I can rely on, if I need a special costumized solution.

Thomas Ochs Luthier – Varnish… Nitrocellulo, P.U (polyurethane) or French polish? What are your choices and why?

When it comes to finishing my instruments, it is the same as with the building process: I want to finish my instruments by myself and offer various options.

On my acoustic instruments I prefer a thin nitrocellulose finish for the body and oil/wax for the neck.

On classic guitars I offer french polish for the top, but whenever possible I try to convince the player to go for nitrocellulose for the back and sides.

Shellac may be considered as the holy grail soundwise, but I believe that my nitrocellulose finish is ultra thin and leaves the instrument as resonant as a french polished one, but with much better protection against sweat, body heat and wear and tear.

On my electrics nitrocellulose is the way to go. You can create a beautiful gloss, with nice colours and impressive depht and have a good protection.

Polyurethan or polyester are no option for me, because they tend to be too thick. I do not want to have an instrument meant to be resonant being packed in plastic.

How do you help your customers choose their electro-acoustic sensors?

At first I need to know, what is the expectation and what are the needs of the costumer.

Then I try to find the system, which meets best the expectations.

Over the years I have installed many different systems, so I think I have a good knowledge about the pros and cons.

But I am also looking for new systems, especially for classical guitars. I think there is some room for innovation left in this field.

How do you help your clients choose the woods for the fingerboard of their instrument in relation to the sound they want to achieve? Can you tell us how this choice affects the other woods used in the construction of an instrument?

The fingerboard of a guitar is traditionally made from the hardest and most dense woods available.

Ebony has proven to be the first choice for classical guitars and works well on all other types.

For electric guitars., there is a much wider array of usable woods, and I am convinced, that we should try to substitute tropical hardwoods with european alternatives.

We have the responsibility to increase ecological sustainability in instrument building.

For my “Model One” I have very good experience with smoked eucalyptus or high qualitiy bog oak fingerboards, which can easily replace rosewood or ebony.

Furthermore I am not convinced, that there is the typical rosewood sound or the typical ebony sound.

We know, that in the same wood species we have a broad range of mechanical properties that directly corelate with the acoustical properties.

I think that the sound you want to achieve is determined by the whole concept of the neck and the fingerboard wood is only one component.

The way to go for me is: Setting a goal for the desired acoustical properties of the part of the guitar I am working on and then choose the woods and construction method.

In addition the customer’s aesthetic demand should not be forgotten.

Thomas Ochs Luthier – Are you also interested in making amps and effects? And, if not, are you going to go in that direction like many other luthiers ? Or do you prefer to leave this part to others? (If you know the names of friends who are in this field, can you name some of them? 😉 )

I am not into electronics at all.

I can wire electric guitars and basses, I installed a few midi systems and sustainers, but when it comes to amps and effects I am definitely out.

As I mentioned before, I try to focus on building and improving my instruments to make sure they are top notch.

Amps, effects, pedals and pickups – for each of these you can find specialised companies, where the player can get highend quality products.

Why should I try to compete in a field where I know, that I am not good?

Thomas Ochs Luthier – Do you have any advice for future young luthiers? Can you give them advice on training courses? Do you know of any special schools?

I was part of the expert commission for restructuring the training regulations of the handicraft trade “Zupfinstrumentenmacher” here in Germany.

The vocational training system in Germany is based on a “dual” system of training, where the training takes place at a company and at a vocational school in tandem.

That means, that you can start your lutherie career as apprentice at a company.

The advantage is that you even earn a little bit of money, but places are extremely limited as only a handful of companies offer these apprenticeships.

The good thing is, that the both vocational schools offer fulltime apprenticeships at the school.

There you do not earn money, but you can concentrate on learning the craft without the need to be part of a production.

These are the schools: https://www.instrumentenbauschule.eu/en/ and http://www.bsz-reichenbach.de/a_zim.html

The profession of Luthier is a trade that requires a significant material investment to start its activity. What would you advise a young luthier to buy to start? The minimum required? And, the maximum to be in a comfortable working environment?

The most important resource of a luthier is his stock of useable tonewood.

When I started as apprentice I also started to buy wood, because I knew that it must be seasoned before I can use it.

Chisels, planes or a router can be bought and are ready for immediate use.

A fresh cut spruce top for a classical guitar is not.

Knowing this, my advise for young luthiers is: Buy tonewood as soon as possible.

Even if you are in one of Germany´s lutherie schools, where you are supplied with wood for your first instruments.

You will need high quality tonewood for instrument to build them. And that means wood for necks, fingerboards, tops, sides, back, bindings, linings, braces, etc.

And grab the chance to buy old wood, if you have it. The older the better. Your 1.5 k router won´t help you, if your tops warp, twist or crack.

You can contact Thomas Ochs Luthier

using the contact form on his personal page on Luthiers.com here :

https://luthiers.com/listing/thomas-ochs-gitarrenbau/

We also invite you to follow him on his various social networks:

- Facebook: https://www.facebook.com/ochsgitarrenbau

- Instagram: https://www.instagram.com/ochs_guitars/

- Website: https://www.ochs-gitarrenbau.de

Thomas Ochs Luthier Interview 1 Background

In the coming weeks, as for others luthiers for plucked string instruments, luthiers for bowed string instruments, amps & effects makers, wood & supplies dealers, lutherie events, jobs, schools & teachers subscribers on our site, you will be able to follow our series of mini-interviews dedicated to the fascinating world of luthiers.

See you soon…

#luthiers

Subscribe to the newsletter!

Subscribe to our newsletter to follow all our news and those of our luthiers.

If you are passionate about the world of luthiers, join us!